Our other innovative materials for your sealing solutions

Chromex benefits from several available materials or with short time delivery. Beside elastomers, plastics or fibres, we can provide you with a wide range of other materials.

Untearable gasket paper

Untearable gasket paper (as Flexoid™) is an inexpensive material mainly used in the automotive industry. These seals can be found in carbs, in oil sumps or engine oil filters. This material is composed of cellular fibres and a gelatinous and plasticizing binder. Untearable paper seals are resistant to liquids such as hydrocarbons, water and oils. Chromex has thicknesses from 0.1mm to 3.2mm on stock, in order to produce your cut gaskets as soon as possible.

Graphite

Graphite is mainly used for industrial applications but also in the petrochemical industry due to its specific mechanical and chemical properties. Therefore, expanded graphite sheets are used to ensure sealing in bolted connections. This material is composed of mineral expanded graphite which can be reinforced by one of the below sheets :

- Smooth stainless steel (shape of strap)

- Stainless steel with spikes (shape of strap)

- Smooth stainless-steel multilayer

Standard thicknesses for graphite cut gaskets range from 1 to 3 mm and can resist to extreme temperatures (up to 800°C).

Felt

Chromex has available stock of felt with thicknesses from 1 mm to 10 mm. Felt is perfect to protect from dust, withstand shocks (avoiding two metal parts to be pressed together) or soundproofing (some part). Wool felt (or mix between wool and viscose) is a very technical material which specific densities range from 0.15 to 0.9 kg/dm3. We can manufacture finished cut gaskets in technical felt but also in shape of stripes or rolls.

Chromex can also provide approved adhesive railroad felt seals (with EN45545-2/2013 approval).

Mica

Chromex disposes of a specific material for applications undergoing very high temperatures (peak temperatures up to +1000°C). Mica can be found in heat exchangers, , gas turbines, refineries, gas and oil burners. This material is composed of phlogopite mica flakes (90%) and a silicone binder (10%) which provides low thermal conductivity. Mica is therefore a great heat and power insulator. Mica has some other significant assets that are worth to be mentioned: it benefits from a good abrasion resistance and excellent compression set.

The important thing about using Mica, is to ensure that your cut gaskets must be sufficiently compressed when mounted in order to avoid deterioration by high temperatures (silicone binder deteriorates by temperatures above 280°C).

We can produce Mica cut gaskets with thicknesses between 0.5 et 3mm.

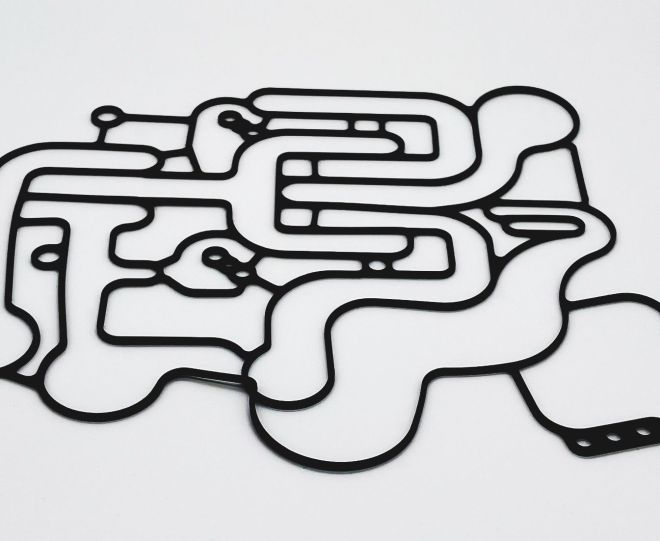

Cork

Cork is to be found in cut gaskets with a nitrile binder (NBR). This material resists to the different existing hydrocarbons, gasoline and oils. Cork with nitrile binder (NBR) is mainly used to produce engine gaskets for the automotive industry but also in the pumps and valves sector: oil sumps gaskets, pump gaskets and gearbox gaskets. Rubber agglomerated cork is also used for the manufacturing of block seals or for soundproofing insultation.

We are able to produce standard cork cut gaskets with thicknesses between 1 and 5 mm.